Copyright © 2025 Meiyuan Precision Technology Co., LTD.

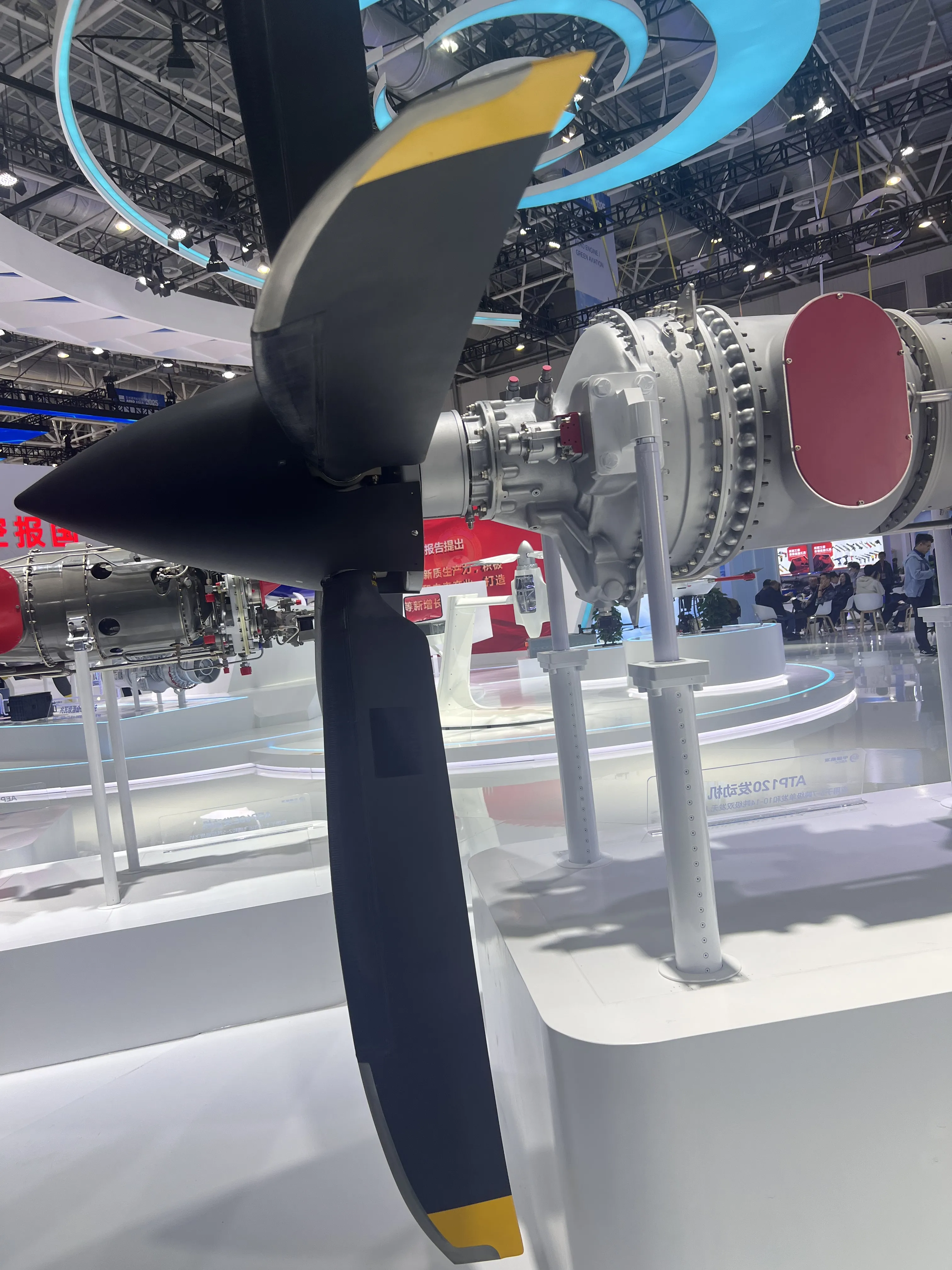

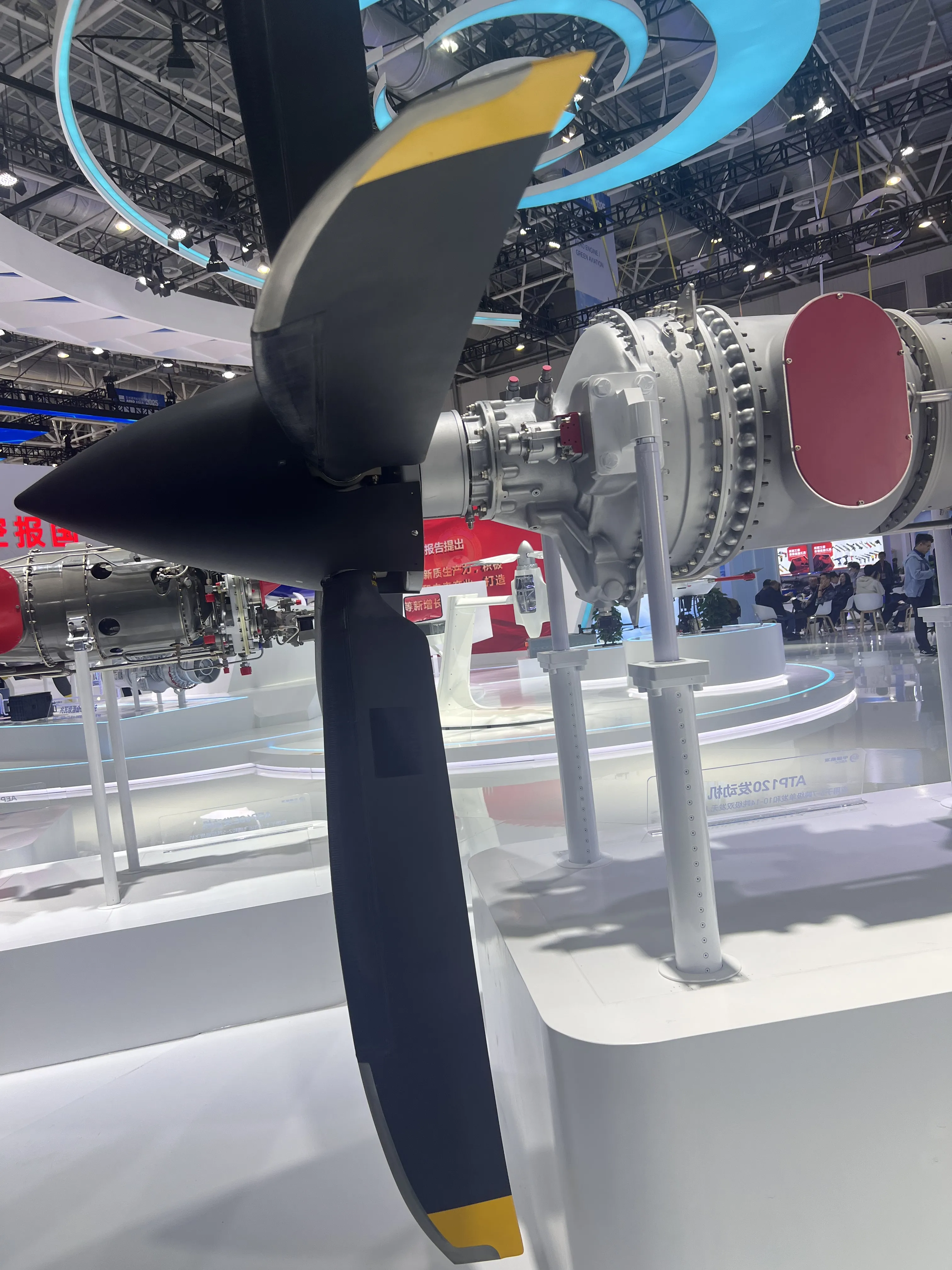

Why is edge metal protection necessary for carbon fiber propellers?

2025-12-01

This is a highly specialized and critical issue. The application of edge metal protection (commonly referred to as "leading-edge protection" or "anti-erosion sleeve") to carbon fiber propellers is a key design detail in aerospace engineering, primarily for the following reasons:

Although carbon fiber composites exhibit extremely high specific strength (strength-to-weight ratio) and excellent fatigue resistance, they have certain weaknesses in specific aspects. The metal sheath (typically made of nickel or stainless steel) is designed to compensate for these shortcomings.

Summarize the following core factors:

1. Resistance to wear and erosion is the most direct and primary reason.

Rain, dust, and particulate matter erosion: Propellers, especially aircraft propellers, when rotating at high speeds, their leading edges violently collide with raindrops, ice crystals, dust, insects, and other tiny particles in the air. Although the force of a single impact is small, billions of impacts over the years can produce a powerful 'erosion' effect. It's like a high-pressure water gun can cut steel plates.

The weakness of carbon fiber: Carbon fiber is composed of brittle carbon fibers and a resin matrix. This continuous impact will gradually grind off the resin on the surface, expose and damage the internal fibers, resulting in a serious decline in material properties, surface roughness, pits, and even delamination.

The advantages of metals: Metals such as nickel or stainless steel have extremely high toughness and hardness, which can effectively resist this microscopic erosion. They can absorb and disperse the impact energy, and only experience slow wear on themselves.

2. Prevent stratification and moisture intrusion

The layered structure of carbon fiber: Carbon fiber composite materials are formed by stacking and curing layers of prepreg cloth.

Edge fragility: The leading edge of the propeller is the weakest and most critical part of the entire structure. Once a small gap appears on the leading edge due to erosion or accidental impact (such as bumps during ground operations), it is easy for the gap to expand under high-speed centrifugal force and aerodynamic loads, causing delamination between layers.

Moisture issue: Once delamination or microcracks occur, moisture can easily infiltrate the interior of the material. This not only increases weight, but more importantly, in low-temperature environments, internal icing can further expand damage. Moisture can also have a long-term impact on the performance of resins.

The function of metal sheath: As a sturdy overall barrier, the metal sheath perfectly protects the edges of the carbon fiber laminate, fundamentally preventing the initiation of delamination and the entry of moisture into the channel.

3. Maintain optimal aerodynamic performance

Surface smoothness is crucial: like wings, the aerodynamic efficiency of propellers is highly dependent on the shape and smoothness of the leading edge. A perfect, smooth, and sharp leading edge ensures smooth airflow attachment, reduces resistance and noise, and improves efficiency.

The consequences of carbon fiber wear: If the leading edge of the carbon fiber is eroded, becoming rough and covered with pits, it will disrupt laminar flow, increase resistance, reduce propulsion efficiency, and may produce greater noise.

The guarantee of metal sheath: The tough metal sheath can maintain the design shape and smoothness of the leading edge for a long time, ensuring that the propeller has stable and efficient aerodynamic performance throughout its entire life cycle.

4. Enhance local impact resistance capability

Although carbon fiber has high overall strength, it is highly sensitive to point impacts from sharp objects such as falling maintenance tools or bouncing ground debris, which can easily cause internal damage that is not visible to the naked eye.

Metal sheaths, especially tough titanium alloys, can effectively resist such unexpected impacts, absorb energy, and protect the fragile carbon fiber structure inside.

Therefore, adding metal leading edge protection to carbon fiber propellers is a typical composite design that maximizes strengths and avoids weaknesses. It combines the lightweight and high strength of carbon fiber with the toughness and wear resistance of metal, ultimately creating a propulsion system that is both efficient, durable, safe, and reliable.

This is a highly specialized and critical issue. The application of edge metal protection (commonly referred to as "leading-edge protection" or "anti-erosion sleeve") to carbon fiber propellers is a key design detail in aerospace engineering, primarily for the following reasons:

Although carbon fiber composites exhibit extremely high specific strength (strength-to-weight ratio) and excellent fatigue resistance, they have certain weaknesses in specific aspects. The metal sheath (typically made of nickel or stainless steel) is designed to compensate for these shortcomings.

Summarize the following core factors:

1. Resistance to wear and erosion is the most direct and primary reason.

Rain, dust, and particulate matter erosion: Propellers, especially aircraft propellers, when rotating at high speeds, their leading edges violently collide with raindrops, ice crystals, dust, insects, and other tiny particles in the air. Although the force of a single impact is small, billions of impacts over the years can produce a powerful 'erosion' effect. It's like a high-pressure water gun can cut steel plates.

The weakness of carbon fiber: Carbon fiber is composed of brittle carbon fibers and a resin matrix. This continuous impact will gradually grind off the resin on the surface, expose and damage the internal fibers, resulting in a serious decline in material properties, surface roughness, pits, and even delamination.

The advantages of metals: Metals such as nickel or stainless steel have extremely high toughness and hardness, which can effectively resist this microscopic erosion. They can absorb and disperse the impact energy, and only experience slow wear on themselves.

2. Prevent stratification and moisture intrusion

The layered structure of carbon fiber: Carbon fiber composite materials are formed by stacking and curing layers of prepreg cloth.

Edge fragility: The leading edge of the propeller is the weakest and most critical part of the entire structure. Once a small gap appears on the leading edge due to erosion or accidental impact (such as bumps during ground operations), it is easy for the gap to expand under high-speed centrifugal force and aerodynamic loads, causing delamination between layers.

Moisture issue: Once delamination or microcracks occur, moisture can easily infiltrate the interior of the material. This not only increases weight, but more importantly, in low-temperature environments, internal icing can further expand damage. Moisture can also have a long-term impact on the performance of resins.

The function of metal sheath: As a sturdy overall barrier, the metal sheath perfectly protects the edges of the carbon fiber laminate, fundamentally preventing the initiation of delamination and the entry of moisture into the channel.

3. Maintain optimal aerodynamic performance

Surface smoothness is crucial: like wings, the aerodynamic efficiency of propellers is highly dependent on the shape and smoothness of the leading edge. A perfect, smooth, and sharp leading edge ensures smooth airflow attachment, reduces resistance and noise, and improves efficiency.

The consequences of carbon fiber wear: If the leading edge of the carbon fiber is eroded, becoming rough and covered with pits, it will disrupt laminar flow, increase resistance, reduce propulsion efficiency, and may produce greater noise.

The guarantee of metal sheath: The tough metal sheath can maintain the design shape and smoothness of the leading edge for a long time, ensuring that the propeller has stable and efficient aerodynamic performance throughout its entire life cycle.

4. Enhance local impact resistance capability

Although carbon fiber has high overall strength, it is highly sensitive to point impacts from sharp objects such as falling maintenance tools or bouncing ground debris, which can easily cause internal damage that is not visible to the naked eye.

Metal sheaths, especially tough titanium alloys, can effectively resist such unexpected impacts, absorb energy, and protect the fragile carbon fiber structure inside.

Therefore, adding metal leading edge protection to carbon fiber propellers is a typical composite design that maximizes strengths and avoids weaknesses. It combines the lightweight and high strength of carbon fiber with the toughness and wear resistance of metal, ultimately creating a propulsion system that is both efficient, durable, safe, and reliable.